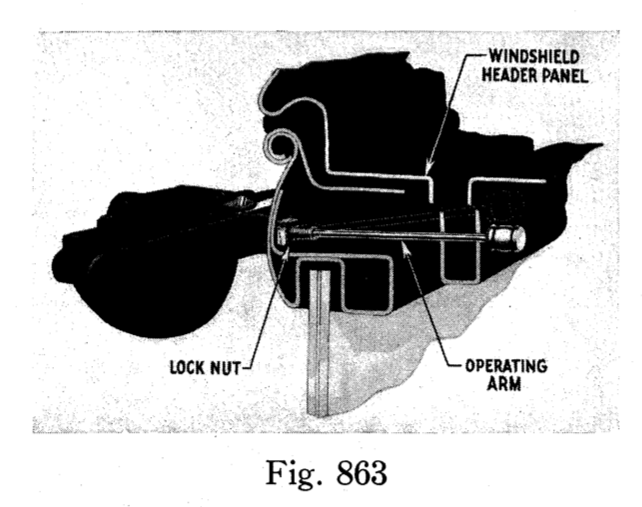

Occasionally a complaint was received that the windshield wiper operating arm sometimes rubbed against the windshield header finish panel, making it difficult to operate the blade. This was caused by insufficient clearance be- tween bottom of lock nut and windshield header. As a result, when tightened there was a tendency on the part of the nut to climb the radius at the bottom of the windshield header and slightly cock the operating arm (see dotted outline. Fig. 863). ·

If an instance of this kind is brought to your attention, it can be corrected by filing or grinding the bottom of the nut until there is sufficient clearance between nut and windshield header.

In production we are now using a special lock nut A-21670-S7 which provides ample clearance between lock nut and windshield header.