Winter electrical troubles are principally due to the effect of cold weather on the electrolyte in the battery, and failure on the part of mechanics to correctly adjust the generator charging rate in owners’ cars to meet the conditions under which the cars are operating.

Cold weather battery and bulb troubles can be. considerably lessened if you will instruct your owners in a few simple things: For example, the proper oil to use in the engine for winter operation. The correct way to use the choke so as to get a quick, easy start, thus lightening the load on both starting motor and battery. It may surprise you to know that it takes approximately 20 minutes running, with the generator set at aver- age charging rate to replace in the battery the current taken out by one minute’s use of the starting motor. When parking at night, even for a few minutes, use the park- ing lights rather than leave the bright lights on.

Hard Starting Resulting in Run Down Batteries

At zero temperatures the starting ability of a battery is reduced to one-half its normal capacity, and its internal resistance proportionately increased. In other words, a battery that will crank the engine for five minutes at normal temperatures, will only crank it 21⁄2 minutes at zero temperatures, and only about half as fast. In addition, the amount of day- light driving is considerably reduced. Also due to congealed oil, the engine is stiff and requires considerably more power to turn it over. These conditions often result in a battery becoming partially or fully discharged.

When trouble of this kind is experienced, the remedy is to increase the generator charging rate by 3 to 5 amperes.

Do not use the ammeter on the instrument panel to adjust the generator charging rate. A master ammeter must be used for this purpose. (K. R. Wilson of Buffalo, N. Y., furnishes a device of this kind.)

Bulbs Burning Out

In cold weather the generator voltage is considerably higher than normal. This is sometimes noticeable by the bluish white color of the light from the bulbs. The increased voltage is caused by the low temperature of the electrolyte which increases the internal resistance in the battery, and in order to maintain a constant charging rate, the generator voltage correspondingly increases.

When bulbs burn out prematurely, it is because they are operating at too high a voltage as a result of poor or loose connections in the battery-generator circuit or due to the charging rate being set too high. The bulbs are designed to burn 100 hours at 6 1⁄2 volts. If the voltage goes up to, say, 7 1⁄2 volts, the bulbs will last less than 25 hours.

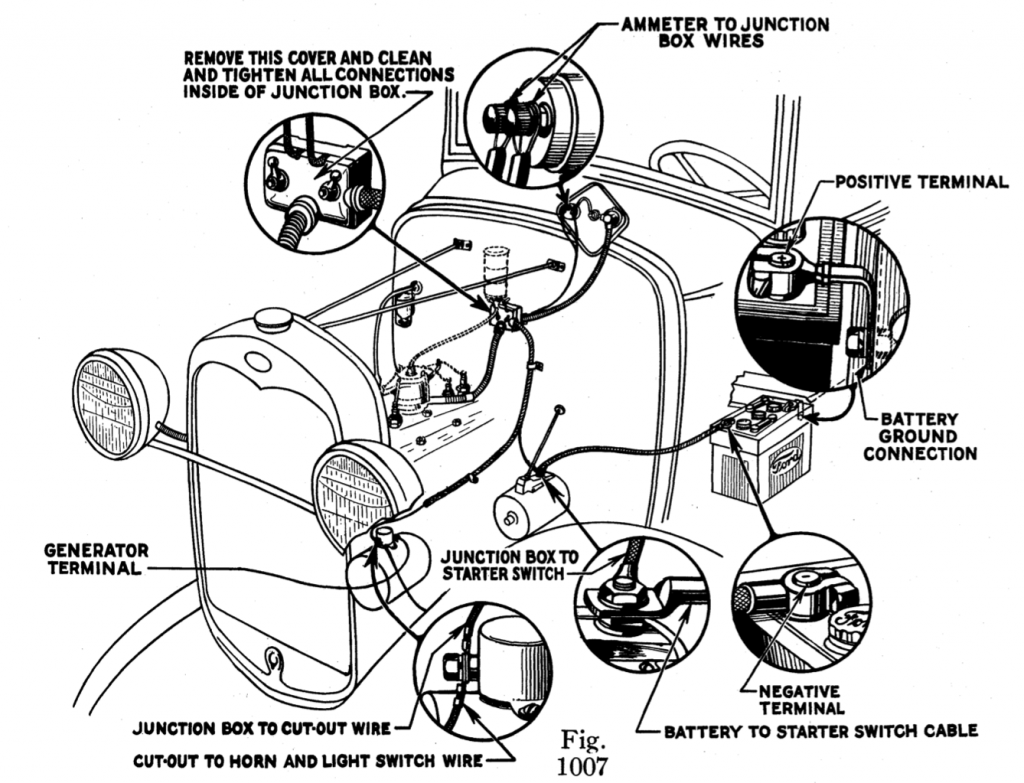

The remedy in such cases is to first make certain that all connections in the battery- generator circuit are clean and tight, especially at the battery terminals, ground connections, and cut-out (see Fig. 1007). Any loose connections build up resistance and cause high generator voltage. Any connections found loose should be taken apart, cleaned, and securely tightened. Nuts and screws should have washers under them.

Special attention should be given the battery terminals, as these are especially subject to corrosion. Take battery terminals off, clean thoroughly with ammonia, coat with vaseline and reassemble, tightening securely. If this is done two or three times a year, no trouble from corroded terminals should be experienced. If the connections are all 0. K. but the bulbs continue to burn out, it will be necessary to cut down the generator charging rate approximately 2 to 4 amperes. Care should be taken, however, not to cut the generator charging rate too much or the battery will become undercharged. If it is necessary to reduce the charging rate to prevent lamps burning out, the gravity of the battery should be recorded at that time and an inspection made after the car has been driven 500 to 800 miles to note whether or not the gravity is falling off. If the gravity is rapidly falling off, it will be necessary either to slightly increase the rate or give the battery a bench charge. Otherwise, the battery may fail to turn the engine over if the weather is extremely cold.

Find out the Condition Under Which the Car is Operated

When an owner complains of battery trouble or frequent lamp bulb failure, make it a rule to find out from him the condition under which his car is being operated.

Find out whether the car is operated mostly at night or during the daylight; whether it is used principally on long trips with comparatively few stops, or on short trips with numerous stops. With this information you can then adjust the generator charging rate to suit the operating needs of the owner. No set rule can be given for generator output setting, but in general, 2 to 4 amperes higher charging in cold weather than in sum- mer should take care of the increased demands on the battery.

Battery can be used as Guide in Determining Correct Charging Rate

In determining whether the generator charging ate is too high or too low, the battery can be used as a guide. For example:

If three or more successive hydrometer readings taken at 500 mile intervals show a consistent loss in gravity, the charging rate should be increased approximately 3 amperes. On the other hand, if the readings show be- tween 1.270 and 1.285 and the electrolyte level is consistently low, the charging rate should be reduced 2 to 4 amperes.

After changing the charging rate, successive readings should be taken and recorded and the process repeated until the battery registers no consistent loss of gravity or does not use an excessive amount of water.

A correctly set generator charging rate will do more to correct battery and bulb complaints than anything else.

If Starting Motor, Electric Windshield Wiper or Horn Fails to Operate or Generator Fails to Charge

In cold weather lubricating oil sometimes congeals and hardens on the commutators in the above parts, causing a coating of insulation between the commutator bars and the brushes. Under these conditions the 6-volt current supply is of too low tension to force current through this coating of insulation and consequently the part fails to operate. If cleaning off the congealed oil and grease does not remedy the condition, the source of trouble can be traced to loose or poor contacts or connections.

In addition to a dirty commutator, the generator should also be checked for worn brushes. If the brushes are badly worn, they should be replaced. If the commutator is dirty or slightly rough, polish it with 00 sandpaper. Be sure to blow out any sand or particles after polishing.