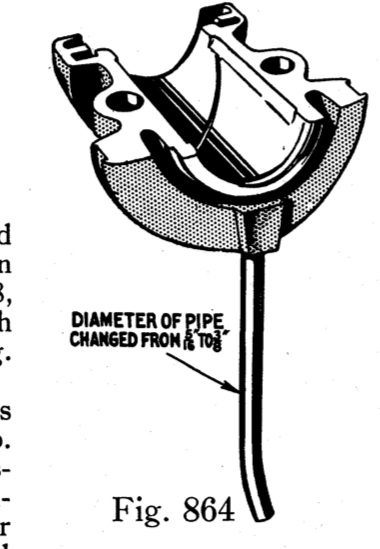

BEARING CAP OIL PIPE CHANGED

The size of the crankshaft rear bearing cap oil pipe has been changed from 5/16”to 3⁄8” (see Fig. 864). Increasing the size of the oil pipe allows the oil to drain more quickly from the main bearing into the oil pan tray especially in cold weather.