Installing Piston Pins

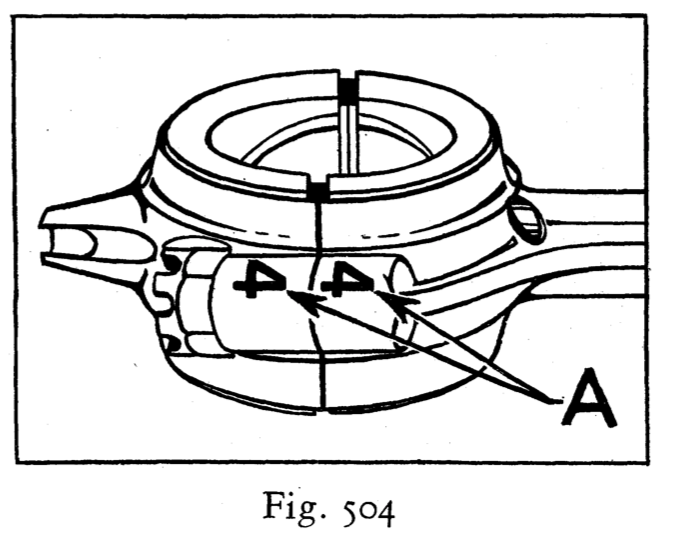

((618)) Under no circumstances should a hammer be used on the piston pin pilot and driver when installing a piston pin. Immersing the piston in boiling water for a minute or two will expand the piston pin hole sufficiently to permit easy installation. To correctly install pin first insert the piston pin pilot and driver …